Malting Barley Storage and Bin Management

By Jan Adamson / September 2019

Jan is a Barley Agronomist based in Fairfield, MT. Jan has worked for Anheuser-Busch in Fairfield, MT for 31 years and has been a Northern Montana agronomist for almost 4 years.

Barley storage and bin management are key factors to help ensure stored barley is maintained after harvest until delivery to the elevator.

Storage Preparations

It is important that bins and equipment are adequately prepared prior to barley harvest to ensure they are ready to receive grain. Bins should be adequately sealed to ensure that no moisture leaks onto the grain. Clean empty bins and augers thoroughly to ensure there is no old grain or other debris to risk new grain contamination. Spray the storage bins with AB approved pesticide to kill any existing insects and help avoid a breeding ground for insects that will damage malting barley.

It is also important to have clean combines and trucks prior to harvest. As an added precaution, run a few bushels through the cleaned combine onto the ground to ensure any existing grain that did not come out in the clean is gone.

Bin Site Maintenance

To ensure good quality storage, it is also important to maintain a proper bin site. The bins should be checked monthly for moisture, and to ensure bins are properly sealed. It is also important to have a clean bin site - no trash, debris, or weeds near the bins.

Bin Samples

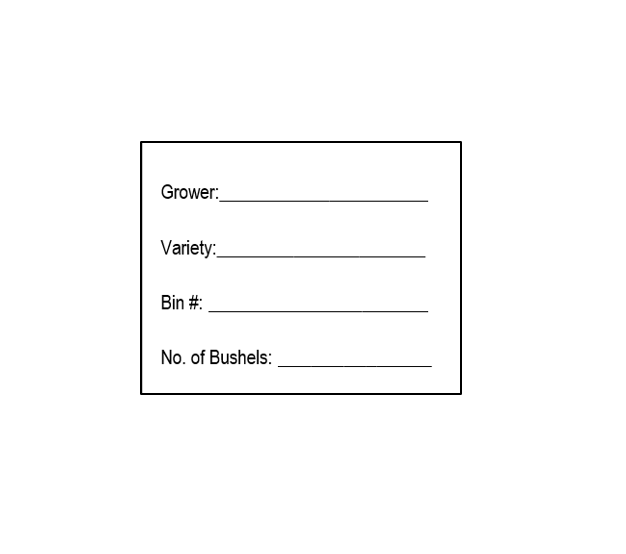

Your goal should be to get an accurate representation of the barley in the storage bin. Lab results are only as accurate as the sample provided. Take a sample from the end gate of the truck or grain cart several times through the unloading process and place it in a sealable container. Cover the sample between loads to avoid moisture loss and contamination. Be sure to accurately identify the sample. You will need to have Grower/Contract Name, Variety, and approximate bushels of barley in the bin. This information should be placed inside the container or adequately attached to the container to ensure there is no loss of information for the sample.

Bin sample grades will provide you with the quality of the barley stored in the bin and will aide in bin monitoring and maintaining your high-quality malting barley until delivered. Bin samples are required prior to receiving any stored barley at your Anheuser-Busch facility.

Additional Proper Barley Storage Information

To ensure barley makes grade, it is important the barley condition from the field is good. Good quality at storage means the barley is harvested correctly - which includes low skinned and broken, clean barley, no trash and low enough moisture for the barley to store well. Too high of moisture can cause heat damage while the grain is being stored.

Avoid overfilling your bin, and as soon as possible after filling the bin, invert the cone and deliver a load. It is very important there are no chemicals on the barley to maintain high quality malting barley.

After filling the bin, use aeration to cool the grain to near outside air temperature, running aeration frequently and long enough to lower the grain temperature.

Bin Monitoring

Bins should be checked at least once a month for off odors, heat build-up and/or damage and insects. Bin bug probes are a good tool to aid in checking for insect activity. These plastic probes should be placed in the upper portion of the bin and fastened to the top of the bin. The probe traps live insects, which can be seen when pulling the probe out of the grain during the monthly inspection.

Summary

Accurate bin samples, quality storage preparation, monthly bin monitoring and bin site preparation are extremely important to maintain quality and acceptability of your malt barley.

Contact your Anheuser-Busch Agronomist with any question regarding bin samples and bin storage and monitoring.